Cleanroom Design

Establish an Ultra-Clean Working Environment With Cutting-Edge Cleanroom Solutions From R.P. Fedder

In the dynamic and demanding sectors of pharmaceuticals, healthcare, and life sciences, precision and cleanliness are imperative. At R.P. Fedder, we understand that your cleanroom is more than just a space—it’s the foundation of your operation, where groundbreaking research and critical processes unfold with a clean start. We offer cleanroom solutions, custom-designed to meet the specific needs of your industry or business.

Get a Quote

Turnkey Solutions

We can design and build custom cleanrooms to meet your unique requirements

Flexible Construction

Modular or stick-built options available

Customizable Environment

Hard or Soft Walls, Tunnels, Floors, Lighting, and Ceilings

Advanced Filtration

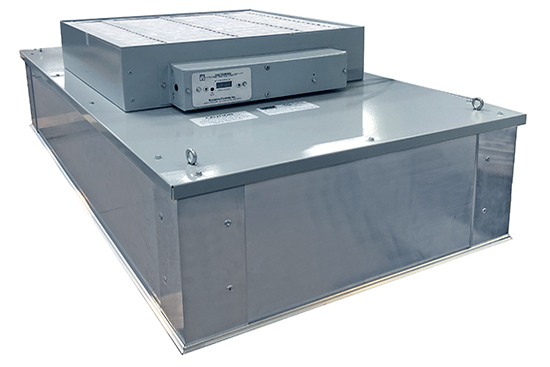

Integrated fan-powered and ducted HEPA filtration systems

Manufacturing, Life Science, and Pharmaceutical Cleanroom Design

At R.P. Fedder, we specialize in providing top-of-the-line clean room solutions tailored to meet the unique needs of high-tech manufacturing, pharmaceutical, healthcare, life science, and semiconductor industries. With our turnkey design-build approach, we leverage our customers’ requirements to create custom solutions that optimize efficiency, precision, and safety.

- Design-Build Turnkey Solutions

- Molecular Cleanrooms

- Hard-wall & Soft-wall Modular Cleanroom

- Micro Cleanroom Tunnels

- Floors, Lighting & Ceilings

- Fan-Powered HEPA Filtration Systems

- Ducted HEPA Filtration Systems

- Laminar Flow Benches

- Cleanroom Products & Supplies (including clean steam generators)

Each of our designs are customized for specific applications. Whether it’s for a pharmaceutical production line, a medical research laboratory, or a biotech facility, every aspect of the cleanroom is tailored to suit the specific needs of the operation it supports. We create cleanrooms that are not only technically proficient but also user-friendly. Comfortable and safe environments enhance productivity and ensure adherence to safety protocols.

At R.P. Fedder, our cleanroom designs are more than just physical spaces. They are environments where precision, safety, and efficiency converge, laying the foundation for groundbreaking work in critical industries. We are committed to transforming your vision into a fully functional, state-of-the-art cleanroom. Get in touch today to see how we can make a difference in your cleanroom design.

Comprehensive Clean Room Capabilities

From simple fume hood installations to expansive 10,000-square foot facilities, R.P. Fedder offers a wide range of clean room expertise. Our proficiency extends from ISO 8- to ISO 3-certified spaces, ensuring that your clean room meets the most stringent industry standards.

We understand that you must be able to precisely control the environment within the cleanroom. Temperature, humidity, and pressure are maintained within strict tolerances through sophisticated control systems, all customized to your needs.

Understanding the ever-evolving nature of businesses, we design our cleanrooms to be scalable and flexible. This allows for easy expansion or reconfiguration, adapting seamlessly to the changing needs of your business. In our all-inclusive designs, we incorporate energy-saving lighting and efficient HVAC systems, among other sustainable practices, to reduce operational costs without compromising functionality.

Design Options Suited to Your Unique Situation

Whether you require a modular clean room or a stick-built facility, we have the expertise to meet your specifications. Our hard-wall and soft-wall modular clean rooms offer versatility and ease of installation, making them ideal for adapting to evolving requirements. Additionally, our experienced team can design and construct floors, lighting, and ceilings that are tailored to your clean room’s unique demands. We design cleanrooms that maximize functionality while ensuring ease of movement and efficient process flow. This involves the strategic placement of equipment such as laminar flow benches and clean steam generators to optimize operational efficiency.

Choosing a Modular Cleanroom System

When selecting a cleanroom system, the modular approach stands out for its versatility and efficiency.

At R.P. Fedder, we specialize in modular cleanroom systems that are tailor-made to meet the requirements of your business. These modular systems offer a balance of precision control and flexibility, ensuring that your cleanroom environment adapts seamlessly to evolving requirements and technology alike.

When our team develops new modular cleanrooms, they are designed with scalability in mind. Whether you’re starting with a smaller setup or expanding an existing facility, our solutions grow with your needs. This adaptability is crucial in rapidly advancing fields where changes in process or scale can occur frequently.

Additionally, our modular cleanrooms are constructed with high-quality materials that meet industry-specific standards. From the air filtration systems to wall and ceiling panels, every component is selected for its durability, functionality, and compliance with industry-specific regulatory requirements.

Easy to Modify and Install

One of the main hallmarks of R.P. Fedder’s cleanroom solution is our ease of modification and installation. Every modular cleanroom is engineered for quick assembly, reducing downtime and accelerating the timeline from concept to operation.

The quick installation process is streamlined and non-disruptive to your business, allowing you to use old cleanrooms that are already in place while the new one is in construction.

The prefabricated nature of modular components allows for a clean and efficient assembly, minimizing the impact on your ongoing operations. Furthermore, modifications or expansions can be made with minimal disruption, thanks to the flexible design of our systems.

Choose R.P. Fedder for Cleanroom Construction Expertise

When it comes to constructing a cleanroom, the choice of your partner is as crucial as the design itself. R.P. Fedder brings over 40 years of expertise in cleanroom design and construction.

Our team of skilled professionals are adept at navigating the logistics and requirements of cleanroom construction, ensuring that your project meets our high standards of quality and compliance.

The R.P. Fedder approach is collaborative and client-focused. We work closely with you to understand your specific needs, challenges, and goals before we even get started. This deep understanding allows us to deliver a cleanroom solution that not only meets – but exceeds – your expectations.

Trust us to build a cleanroom that sets the foundation for your success, whether you are in pharmaceuticals, aerospace, healthcare, life sciences, or any other sector.

Flexible Construction

Customizable Environment

Advanced Filtration

Flexible Construction

Your needs are unique, and so are our construction approaches. Whether you prefer the traditional solidity of stick-built structures or the versatility of modular designs, we tailor each project to your specifications.

Our flexible construction options ensure that your cleanroom adapts to your evolving requirements, future-proofing your investment and keeping you at the forefront of industry standards.

Customizable Environment

Every detail counts in a cleanroom environment.

From the strategic layout of tunnels to the choice of flooring, lighting, and ceilings, we can help you turn your cleanroom vision into reality. Our custom approach means that your cleanroom doesn’t just meet industry standards – it, exceeds them, creating a space that’s functional and truly optimized for your specific needs and requirements.

Advanced Filtration

Our integrated fan-powered HEPA filtration systems are designed to deliver optimal air purity levels, ensuring a contaminant-free environment for your sensitive work and research. With our Lean Six Sigma approach, our filtration technology is a benchmark in the industry where our expertise shines brightest.

Cleanroom Design Considerations

When it comes to crafting the perfect cleanroom environment, it’s essential to understand and address key design considerations.

When you choose R.P. Fedder, you can count on a team that specializes in creating custom cleanroom solutions that meet the demands of your sector.

![]() Our design process begins with a keen focus on regulatory compliance. In an industry where adherence to ISO classifications and FDA requirements is imperative, we meticulously ensure that every aspect of the cleanroom – from HEPA filtration systems to the materials used in construction – aligns perfectly with these guidelines.

Our design process begins with a keen focus on regulatory compliance. In an industry where adherence to ISO classifications and FDA requirements is imperative, we meticulously ensure that every aspect of the cleanroom – from HEPA filtration systems to the materials used in construction – aligns perfectly with these guidelines.

From there, we understand that the heart of any cleanroom lies in its air quality and filtration. Recognizing this, we offer advanced filtration solutions, including ducted and fan-powered HEPA systems. These filtration systems are engineered to maintain the highest levels of air purity, essential for the control of particulates in extremely sensitive environments.

No matter what industry you are building a cleanroom for, the selection of materials during construction is critical. We choose surfaces and finishes that not only facilitate the highest levels of cleanliness but also resist contamination and enhance safety in your particular industry. Our materials are easy to clean, non-particle shedding, and durable against harsh cleaning agents, ensuring that the cleanroom maintains its integrity over time.

Why Choose R.P. Fedder?

Every product in our portfolio is sourced from esteemed manufacturers, ensuring that you receive only the most reliable and high-quality solutions and cleanroom designs. Our commitment to excellence is reflected in each service we provide.

Recognizing that each facility has unique needs, we specialize in providing custom-designed solutions. Our team works closely with you and your builders to understand the requirements of your space, crafting a cleanroom design that aligns perfectly with your objectives.

Local Presence, Global Standards

Based in Rochester, NY, with locations in Amherst and Syracuse, we blend local accessibility with globally recognized standards. We align our practices with international quality standards, ensuring that our services are exemplary on a global scale.

By choosing R.P. Fedder, you benefit from a partner who understands both the nuances of your local needs and the demands of a global market. It’s a partnership that offers the best of both worlds—personalized service and world-class quality.

Advanced Filtration and Airflow Systems

To maintain the highest level of air purity, we integrate systems that effectively remove particles and contaminants from the workspace, creating an environment that promotes optimal cleanliness and product integrity. Fan-powered HEPA filtration systems, ducted HEPA filtration systems, and vertical or horizontal laminar flow benches are among the systems we can specify for your project.

Designed for Flexibility

‘Designed for Flexibility’ means more than just a versatile cleanroom structure. It means providing a solution that adapts to the changing needs of your industry and ensuring that your investment today remains relevant and effective for the challenges of tomorrow.

With our expertise and commitment to innovation, you can be confident that your cleanroom will support the dynamic and flexible nature of your work.

Furthermore, we recognize that the requirements of your cleanroom can change as your operations grow and evolve. This understanding is deeply embedded in our approach to designing cleanrooms that are as adaptable as they are efficient.

Modular Design: Our cleanrooms are designed with modularity at their core. This means you can easily expand, reconfigure, or upgrade your cleanroom as your needs change.

Whether it’s accommodating new equipment, scaling up production, or adapting to new processes, our modular design ensures your cleanroom can evolve with your business. We also understand that no two cleanrooms have identical requirements.

Our solutions include customizable components such as interchangeable wall panels, adjustable airflow systems, and modular furniture and storage units. This allows for easy adjustments to suit different cleanliness classifications, workflows, or equipment layouts.

Future-Proofing Your Technology

In an age where technology rapidly advances, our cleanrooms are designed to integrate with the latest technological innovations. From advanced monitoring systems to automated controls, we ensure that your cleanroom can seamlessly incorporate new technologies as they become available.

Best of all, our filtration systems are designed to be scalable, no matter whether you are using HEPA or ULPA filters. Whether you need to increase the filtration capacity to meet higher cleanroom standards or adjust the airflow patterns for new layouts, our systems can be adapted quickly and efficiently.

We design with maintenance in mind, ensuring that any necessary repairs or upgrades can be carried out with minimal disruption to your operations. This approach not only extends the lifespan of your cleanroom but also ensures that it continues to operate at peak efficiency.

Comprehensive Cleanroom Products and Supplies

At R.P. Fedder we offer an extensive range of cleanroom products and supplies, all meticulously designed to enhance your clean room’s functionality and efficiency. We understand the importance of maintaining your contamination-free space:

- Floors, Lighting & Ceilings

- Fan-Powered HEPA Filtration Systems

- Ducted HEPA Filtration Systems

- Laminar Flow Benches – Vertical & Horizontal

- Clean Steam Generators

- And many more clean room products & supplies

Our products are sourced from trusted manufacturers to ensure exceptional quality and reliability. It’s not just about meeting regulatory requirements; it’s about exceeding them, ensuring your operations are shielded from the slightest contamination. We value quality, and bring this level of service to our comprehensive range of cleanroom products and supplies, each selected to better enhance your cleanroom’s functionality and efficiency.

What are the principles of clean room design?

At the core of every design we create, we stand by they key principles of clean room design. These principles are our guiding light, allowing us to create a custom sanitization space that allows you to do your work without the risk of contamination or damage to research and experiments.

These principles are easy to understand at a baseline, allowing us to break it down into 5 primary concepts:

#1. Contamination Control

#2. Airflow Management

#3. Pressure Differentiation

#4. Temperature and Humidity Control

#5. Material Sustainability

The primary objective of any cleanroom is to control contamination.

This means that a cleanroom must regulate the environment to limit the presence of dust, airborne microbes, aerosol particles, and chemical vapors. For example, in a pharmaceutical cleanroom, the use of HEPA-filtered pass-through chambers is often essential. These chambers allow materials to be transferred into the cleanroom without bringing in contaminants, allowing researchers to maintain a sterile environment.

Effective airflow management is crucial in maintaining a contamination-free environment. The design of the cleanroom must facilitate the appropriate movement of air. At the forefront of managing optimal airflow, we can provide fan-powered and ducted HEPA filtration systems.

Consider a semiconductor manufacturing cleanroom where precise control of particulate matter is critical. Here, the implementation of unidirectional (laminar) airflow can be used to ensure that particles are swept away from the manufacturing area, reducing the risk of contamination.

Maintaining different air pressures in adjoining spaces is vital to prevent cross-contamination. Our cleanroom designs often incorporate controlled areas with higher air pressures compared to adjacent spaces, ensuring contaminants are kept at bay.

For example, in a hospital pharmacy compounding cleanroom, maintaining a higher pressure in the clean area compared to adjacent spaces prevents the inflow of contaminated air. This is typically achieved through carefully engineered HVAC systems.

In many environments, even minor deviations in temperature or humidity can have significant impacts on the integrity of experiments, processes, and product quality.

An example of this principle in action is in a biotech research lab where experiments require specific environmental conditions. Here, the cleanroom design might include advanced HVAC systems capable of maintaining the temperature within ±1°C and humidity within ±5% RH.

Last – but certainly not least – a good cleanroom designer should always think about material sustainability. This isn’t sustainability in the modern sense of the word, but in the sense of durability. Every material used in a cleanroom, from the walls and floors to the ceilings and fixtures, must be non-particle shedding and easy to clean.

At R.P. Fedder, we select materials that not only meet these requirements but also enhance the overall functionality of your cleanroom. For instance, in an electronics assembly cleanroom, static-sensitive components necessitate the use of anti-static materials. This could include ESD (Electrostatic Discharge) flooring, work surfaces, and chairs to prevent static build-up that can damage sensitive electronics.

Or, our approach to cleanroom design is rooted in these principles, ensuring that every project we undertake is aligned with your goals. We perform to the highest standards of quality and efficiency, innovating in the cleanroom and filtration industry with every new project.

By choosing us, you’re not just selecting a product or cleanroom designer, but a partner in design who understands and applies these fundamental principles to deliver a solution that meets and exceeds your expectations.

Partner with R.P. Fedder

When it comes to clean room solutions, R.P. Fedder offers leading-edge supplies to meet your needs. Our commitment to customer satisfaction, combined with our decades of experience, makes us the ideal partner for your clean room project. We take pride in delivering exceptional results that meet your specific requirements while adhering to the highest standards of quality and compliance.

By integrating cutting-edge technologies with best practices in cleanroom design, we ensure your projects exceed the standards of cleanliness and compliance. Contact us today to discuss your clean room needs and discover how our custom solutions can help you achieve your goals.