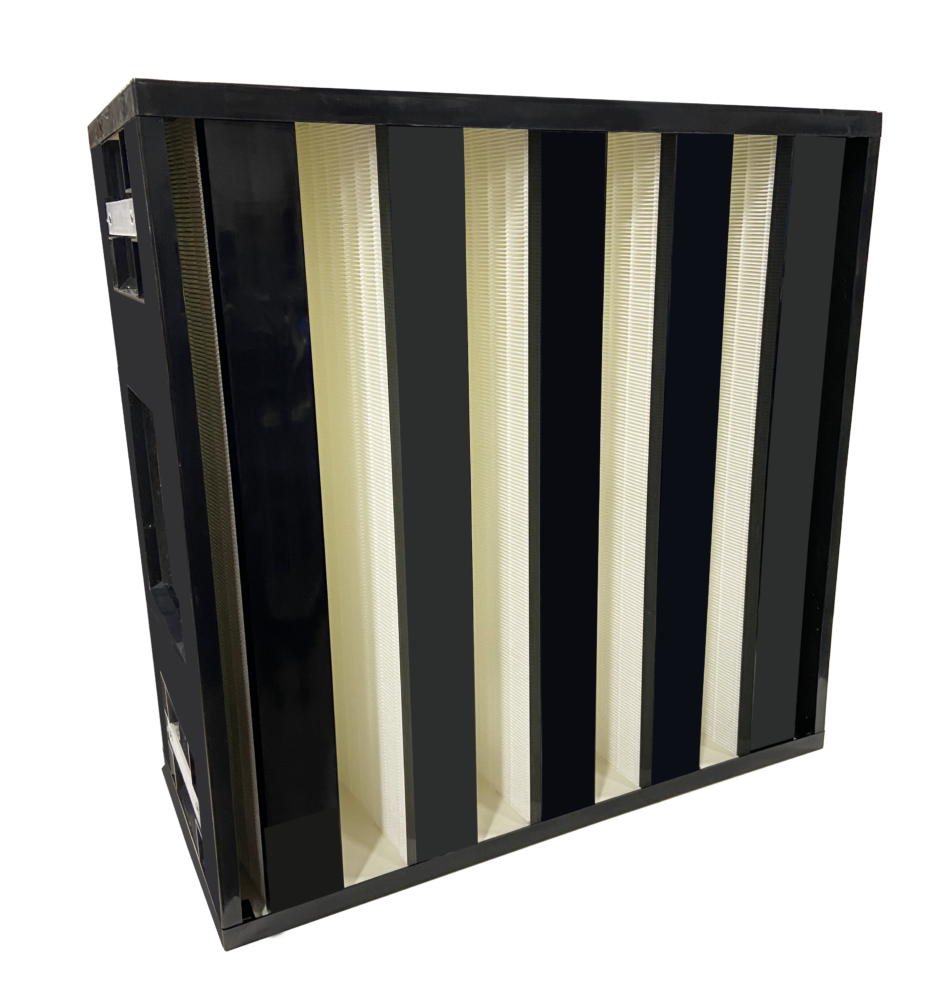

Custom HEPA Filters

The Leading Manufacturer of Custom HEPA Filters for 60+ Years

For over 60 years, the team at R.P. Fedder has proudly designed and manufactured custom HEPA filters for just about every application under the sun. Our knowledgeable air filtration specialists strive to provide both the custom solutions and low-cost pricing you need.

As the leading custom HEPA filter manufacturer in Western New York, we were founded on a passion for air quality and keeping the air clean. Today, that driving force is behind all of our custom air filtration solutions.

Get a QuoteView Case Studies

MERV 8-16, HEPA & ULPA

All the way up to 99.9999% efficient @ 0.3µ

Wide Variety of Materials

Customize your filter media and frames

In-House Testing

Measuring efficiency and pressure drop

What is a HEPA Filter?

A HEPA filter is a mechanical air filter that significantly improves air quality by trapping extremely small particles, including airborne contaminants like mold, pollen, bacteria, and dust.

HEPA is an acronym that’s short for “high efficiency particulate air.” All HEPA filters are designed to remove at least 99.97% of airborne particles that are .3 microns in size.

Many people hear this definition and assume particles bigger or smaller than .3 microns won’t be filtered out. What other reason could there be for the .3 micron specification?

The truth is, HEPA filters are actually tested against the “worst-case scenario.” Particles that are exactly .3 microns in size are the most difficult for a filter to catch, so they’re the baseline anytime we test our custom HEPA filters.

This is why you can expect at least 99.97% of airborne contaminants to be purified. If particles are bigger or smaller than .3 microns, your custom HEPA filters can provide even higher percentages of air filtration.

HEPA Filters Vs. Standard Air Filters

There are several key differences between HEPA filters and what you might call “standard” air filters. Speaking as a custom filter manufacturer with 60+ years of expertise, here’s what you need to be aware of.

Efficiency

Airflow

Applications

Construction

Lifespan

Regulations

Use Cases

Die Cutting

Unlike HEPA filters, standard filters only catch 10 – 60% of particles. Plus, standard air filters can only catch bigger particles ranging from 1 to 10 microns.

Because standard filters have a less dense construction, some people feel they have better airflow. In reality, a correctly matched HEPA filter, appropriate for your particular application, provides much better airflow than a standard one-size-fits-all option.

Standard air filters are well-suited to residential HVAC systems. But in environments where air quality is critical, HEPA filters are a much better option.

HEPA filters are made of thin fibers of glass and activated carbon-based materials. Regular filters are made of porous materials like cotton paper sheets and polyester.

HEPA filters also have a signature mini pleat design, which means their filtration capabilities are much better than a simple standard filter.

Standard air filters usually need to be cleaned and replaced far more often than HEPA filters. HEPA filters can handle a far higher particle load.

These days, every industry has certain standards and regulations. Our custom HEPA filters are designed to meet these requirements. We provide testing and documentation to support compliance with a variety of standards.

HEPA filters can be customized for absolutely any industry and application. Standard filters are more like a one-size-fits-all solution for less critical use cases.

Our high-speed presses handle high volume jobs and our 60” wide press can be used for larger part geometries

Custom HEPA Filter Case Studies

Redesigning Research Cage HEPA Filters

For Form, Function and Financial Goals

A longtime manufacturer of life sciences research cages approached R.P. Fedder when the existing design of the filtration system in the cages was no longer profitable or meeting customer needs.

Meeting Unique Time & Volume Needs

With Flexible Volume Assembly Line Capabilities

A global manufacturer of filters needed a contract manufacturer who could handle time-critical orders from 100 filters up to 1,000’s of filters while maintaining high quality standards.

Benefits of Choosing Custom HEPA Filters

If you’re reading this, there’s a very good chance you already know the differences between HEPA filters and their standard counterparts. But the benefits of custom HEPA filters are far less commonly known.

Better Air Quality

At the end of the day, there’s a perfect tool for every job. Custom HEPA filters guarantee the best possible seal and maximum efficiency, no matter the setting.

Higher Equipment Efficiency

When your HEPA filters are tailored to your specific machinery and systems, you can say goodbye to airflow issues. Your products or equipment will run more smoothly and need less maintenance.

Guaranteed Regulatory Compliance

Every industry has its own air quality protocols. Custom filters always meet these requirements, helping you avoid expensive fines and unexpected shutdowns.

Cost-Effectiveness

You might think of custom HEPA filters as a pricier option. But remember, your investment pays off in the long-term—think lower energy bills and far less maintenance.

Protect Sensitive Processes

Many industries, such as aerospace and laser cutting, use highly sensitive processes every single day. Custom HEPA filters help prevent costly defects and precision issues.

Proven Environmental Impacts

Your custom HEPA filters help your products and / or business reduce energy consumption. Demonstrating this commitment to environmental stewardship can make all the difference with consumers and stakeholders.

Custom HEPA Filters for Any and All Industries

As air filtration design and manufacturing specialists, we’re deeply familiar with just how many industries need personalized, affordable solutions.

We proudly support any and all industries that can benefit from working with a custom HEPA filter manufacturer:

- Aerospace

- Air Cleaning

- Air Purification

- Airline

- Animal Caging Systems

- Appliances

- Cabin Air Filters

- CBRN (Chemical, Biological, Radiological, and Nuclear)

- Chemical

- Cleanrooms

- Construction

- Dental Equipment

- Disaster Recovery Ventilation

- Electrical

- Food and Beverage

- Firefighting

- Fume Collection

- General Industry

- HVAC Equipment

- Hybrid Transportation Equipment

- Industrial Vacuum Systems

- Infection Isolation Rooms

- Integrated Circuit Fabrication

- Laser Cutting

- Life Sciences

- Machining and Milling

- Manufacturing Equipment

- Medical

- Military

- MOCVD

- Negative Air Machines

- Off-Road Equipment

- Petrochemical

- Pharmaceutical

- Powered Air Purifying Respirators (PAPRs)

- Precision Machining

- Protective Environment Rooms

- Remediation

- Room Air Purification

- Semiconductors

- Surgical Smoke Filters

- Surgical Suites

- Transportation

- Welding Fumes

Designed and Manufactured Based on Your Unique Needs

Producing cost-effective, high-quality custom HEPA filters has been at the forefront of our business over six decades. Over the years, we’ve honed our process to make getting what you need as simple and affordable as possible.

Custom Filter Design

Prompt Prototyping

In-Depth Lab Testing

Real-World Field Testing

As one of the long-standing global producers of custom HEPA filters, we specialize in application-driven filter design.

This means so much more than just focusing on a tight seal. We also work with you to ensure meeting the highest bar for performance and quality standards, whatever your end-use scenario.

We understand that the prototype process looks quite a bit different from one industry to another. We use every resource at our disposal—from theoretical modeling to manufacturing functional units—to create the custom solutions you need.

In today’s world, prototyping isn’t enough to know whether our filter design, performance, and function meet every one of your unique needs.

That’s why we perform a litany of tests, from air filter leak testing to fractional efficiency (FE) testing to air filter certification. We’re committed to guaranteeing the integrity of your custom HEPA filters.

In many situations, comprehensive prototyping and lab tests aren’t enough. We also provide field testing to achieve pre-production filter design approval.

This can cause the process to take longer, but certain applications require real-world tests due to environmental conditions. Oftentimes, the results of field tests just can’t be duplicated in lab environments.

Custom HEPA Filters FAQs

Is MERV or HEPA better?

The choice between MERV (Minimum Efficiency Reporting Value) and HEPA (High Efficiency Particulate Air) filters depends on your specific air quality needs. MERV filters are rated on a scale from 1 to 16, with higher numbers indicating greater filtration efficiency. They are effective for general residential and commercial use, capturing particles as small as 0.3 to 10 microns.

HEPA filters, on the other hand, are much more efficient, capturing at least 99.97% of particles as small as 0.3 microns. They are ideal for environments where superior air quality is critical, such as hospitals, cleanrooms, and industries with sensitive processes. While MERV filters offer good filtration for everyday applications, HEPA filters are generally the better choice for achieving the highest level of particle removal and air purity.

Do HEPA filters make HVAC systems work harder?

HEPA filters are denser than standard air filters, which can lead to increased resistance to airflow if not properly matched with the HVAC system. However, when a HEPA filter is customized for your specific HVAC setup, it can effectively maintain good airflow without overloading the system. It’s important to consult with an air filtration specialist to ensure the filter is compatible with your HVAC system and does not put unnecessary strain on it.

How long do custom HEPA filters last?

The lifespan of a custom HEPA filter depends on its usage and environment. Generally, they need less frequent replacement compared to standard filters, as they can handle a higher particle load without compromising performance.

How are custom HEPA filters made?

HEPA filters are crafted from thin glass fibers and carbon-based materials, arranged in a pleated design for optimal efficiency. When you order a custom HEPA from us for your OEM project, each filter is tested for efficiency and pressure drop to ensure it meets your exact specifications.

What is better than a HEPA filter?

While HEPA filters are highly efficient, capturing at least 99.97% of particles as small as 0.3 microns, there are cases where ULPA (Ultra-Low Penetration Air) filters may be considered superior. ULPA filters can capture up to 99.999% of particles as small as 0.12 microns, making them an excellent choice for ultra-sensitive environments, such as cleanrooms and certain medical facilities.

However, HEPA filters are generally more than adequate for most applications and offer a balance of efficiency, cost, and airflow compatibility. The decision between HEPA and ULPA depends on your specific air quality needs and the sensitivity of your environment. Consulting with an air filtration expert can help determine the best option for your application.

Learn More About Custom HEPA Filters from Our Air Filtration Specialists

Please give us a little information, and one of our air filtration specialists will get in touch to discuss custom HEPA filters for your specific needs.